Before — After

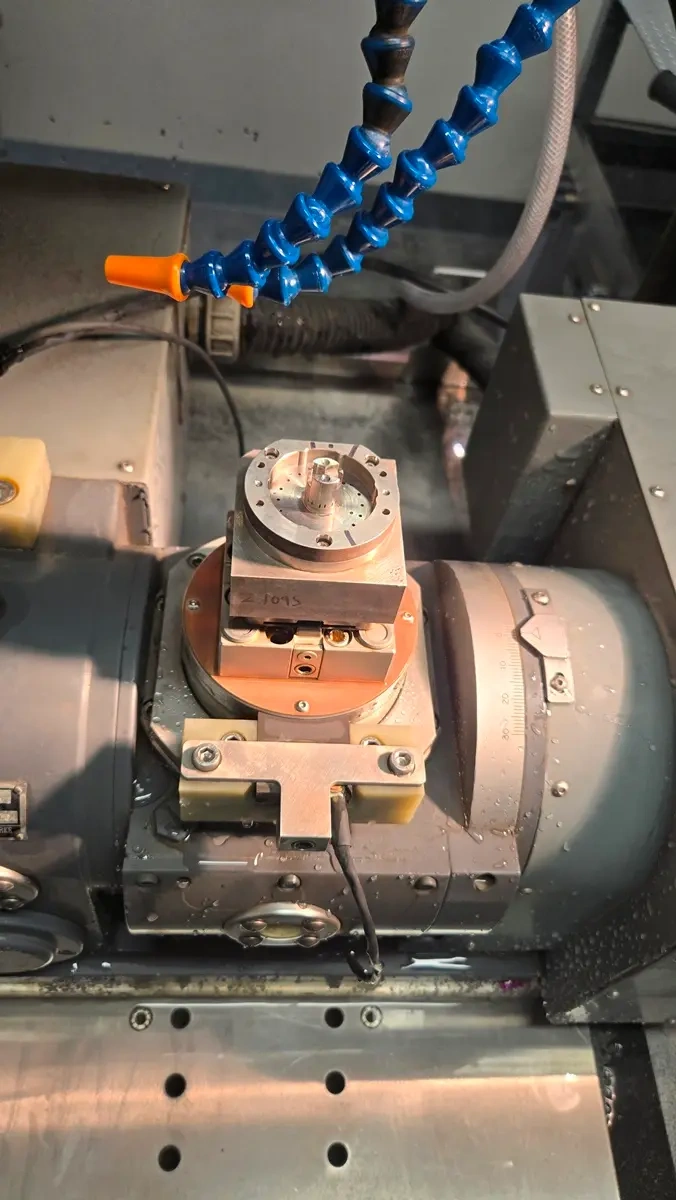

5th Axis Continuous Contact System

The tool ensures smooth 360° rotation while maintaining a flawless electrical connection.

How it elevates your workflow

Unlimited 360° Motion

Now part can rotate endlessly around its axis in just a single direction. No more unnecessary returns to starting position, which leads to shorter machining time.

Stable Electrical Contact

A reliable connection is maintained throughout the entire cycle, even under continuous movement.

No Wire Wear

The connecting wire always stays fixed in place and never wears out, which increases durability and eliminates downtime.

Advantages

Reliable contact in any position

A & B axes can rotate freely without any limits and with no risk of contact loss.

Reduced machine downtime

Fully eliminating the most common reason for machine downtime, saving hours and days of idling equipment.

Long-term reliability

System proved itself with hours of work time in the real EDM shops.

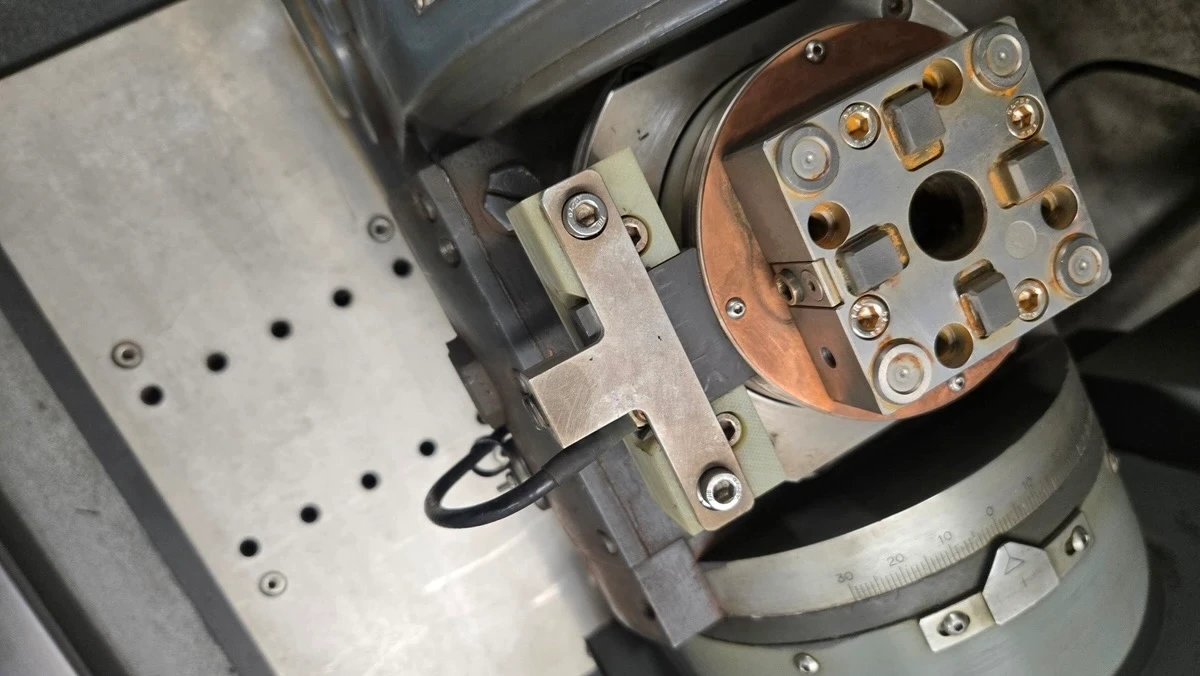

Easy integration

System is installed without any modifications to the machine or 5-axis table. It requires only a fixture with a few extra parts.

Higher production efficiency

Hole poppers no longer have to stop due to cable failures, which drastically increases overall equipment effectiveness.

Designed for NIKKEN tables

By default the system is fully compatible with NIKKEN 5-ax tables 5AX-130 & 5AX-2XX. Custom orders available.

Frequent Questions

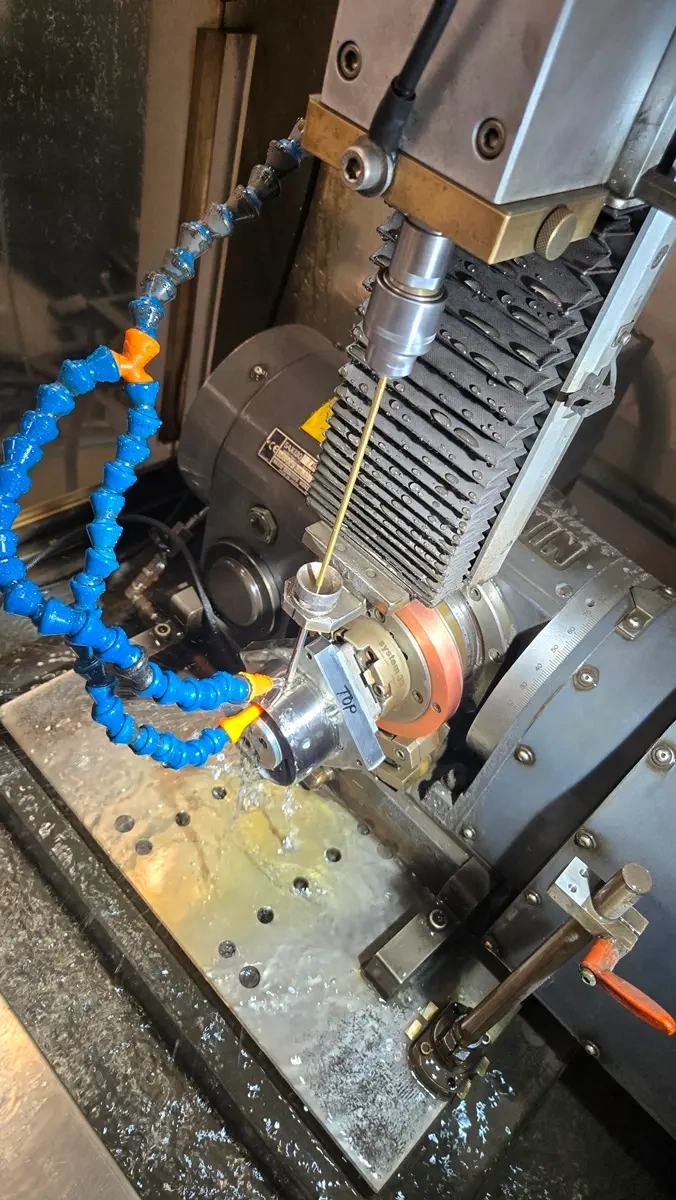

How does it work?

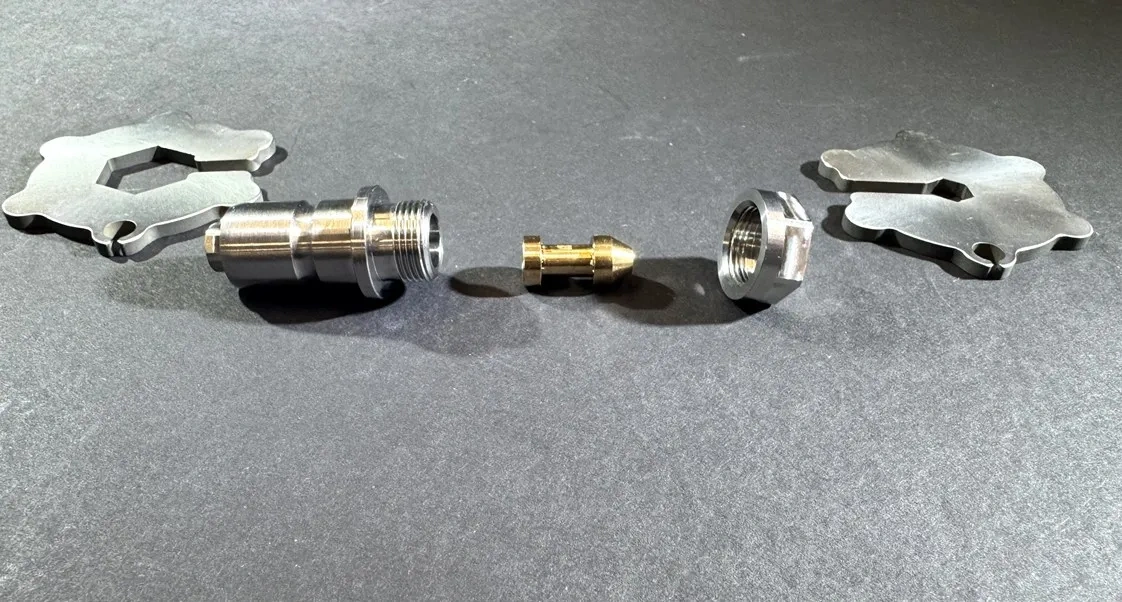

The device mounts to the rotary table on the hole popper EDM. The wire connects to a fixed contact point. A special assembly transfers current to the rotating section. The part consistently receives a stable negative or positive potential, regardless of movement along A and B axes. As a result, motion is limited only by mechanics of the machine while the electrical connection remains uninterrupted at all times.

Which machines is it compatible with?

The system is designed to fit any hole popper EDM machine.

Which rotary tables is it compatible with?

The system is designed to fit NIKKEN 5-ax tables 5AX-130 & 5AX-2XX. Customization and new table support available for other models upon request.

How can i prevent my EDM hole popper cable from tangling and ripping?

By using our special system which will ensure stable electrical contact with part without wire movement.

Where is the device manufactured?

Our system is proudly made in USA, in Poway, CA.

Ready to upgrade your EDM process

To check compatibility, request pricing, place an order or discuss a custom version for your machine, please send us a message or give us a call. We will be glad to help.

Explore Our Other Products

Collet housing & Cover kit (CT)

Professionally made collet housing & cover for CT hole poppers with automatic electrod changer

Collet housing & Cover kit (TITAN)

Professionally made collet housing & cover for TITAN hole poppers with automatic electrod changer